Local manufacturers of Gardner Denver Nash Liquid Ring Vacuum Pumps & Compressors

| Corrosion Protection

About Us

Vac-Cent Services (Pty) Ltd, an ISO 9001:2015 company, was formed in the second quarter of 1987 with the objective of retaining the manufacturing licence for Nash Liquid Ring Vacuum Pumps and Compressors and related products, in South Africa. Major markets being serviced since 1981 still remain Pulp & Paper, Chemicals, Food, Coal, Mining, Power and Waste Water treatment.

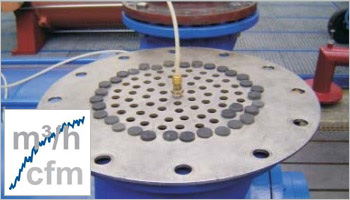

Vac-Cent now manufactures two different sizes Vessel mounted filtrate pumps also 100% locally. These are also available in SG Iron and Stainless steel or a combination of the two materials.

Always striving to offer the market the most current and up to date technology and our Vision is to become the preferred supplier of Vacuum pumps and related products in Southern Africa and in the Indian Ocean Islands.

Our Products

Manufacturers and suppliers of vacuum pumps and related products in Sub-Sahara Africa and Indian Ocean Islands

Our Services

Repairs & Refurbishment

Field Service

Quality Assurance

Corrosion Protection

Service Exchange Pumps

Parts & Spares